Line-following Robot

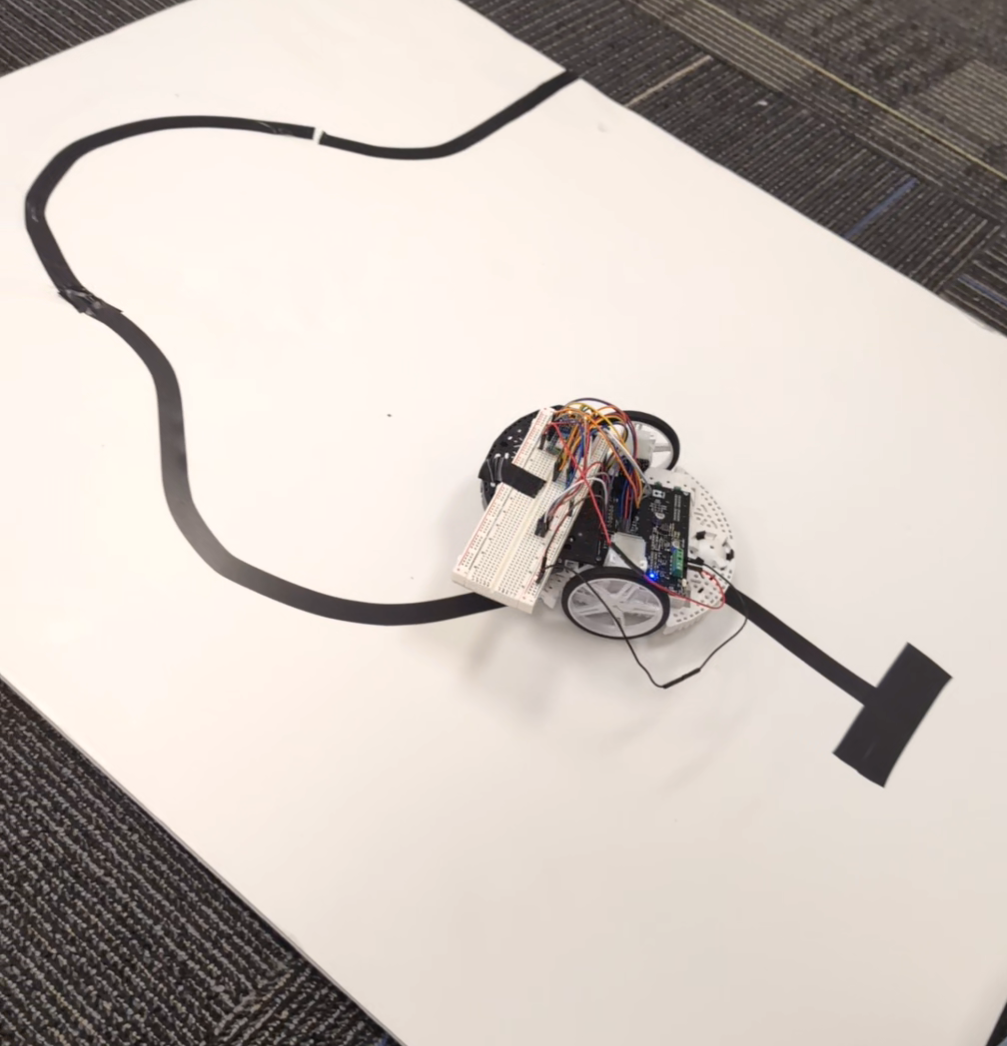

Over the course of several weeks, I worked with a team of selected classmates to build and program a line-following robot from scratch. The project emphasized hands-on skills such as chassis assembly, soldering, wiring, and subsystem integration. We incrementally developed and tested key components, including sensors and motor control systems, while also refining our code through multiple iterations. The final weeks were dedicated to tuning the robot’s performance for speed and accuracy, culminating in a scored competition where the robot navigated a course autonomously. The experience provided valuable insights into robotics, embedded systems, and team-based engineering.

For this project, I was responsible for programming the core functionalities of the line following robot using CircuitPython. I began by implementing sensor polling routines to read data from the reflectance sensor array, which detects the position of the line beneath the robot. Using this data, I developed a PID (Proportional Integral Derivative) control algorithm to dynamically adjust the motor speeds and keep the robot accurately centered on the line. To manage the robot’s behavior during different phases of operation such as starting, turning, or stopping, I implemented a state machine framework. This modular approach allowed for more robust control logic and smoother transitions between tasks. Through iterative tuning and testing, we achieved a fast and reliable line following performance in preparation for the final competition.

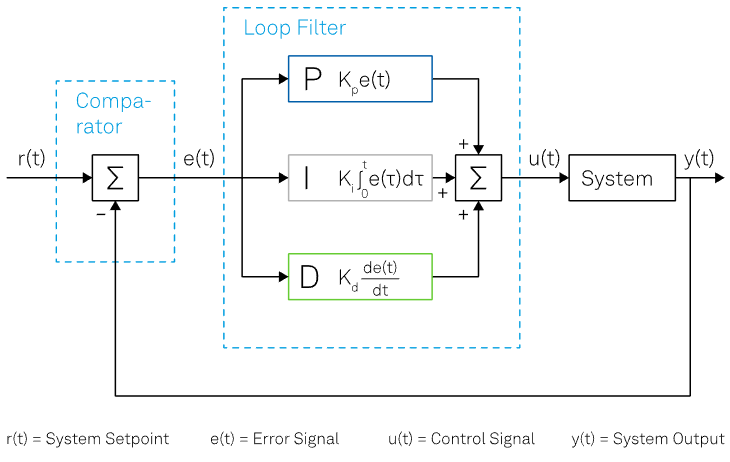

Below is a PID-control feedback system we were introduced to in the class that helps with stabilizing the robot’s movement. A key task I completed was translating the system to code that allowed variables such as proportion, integral, and derivative to be tuned throughout the project.

To implement turning behavior in the line-following robot, my teammates and I structured the control logic using a state machine, where each state handled a specific mode of behavior. In the STATE_TURNS block, I used condition checks to determine whether the robot was detecting black or white surfaces and to trigger transitions accordingly. I integrated the PID controller by instantiating it with tuned parameters (kp_line, ki_line, kd_line) and calling it to calculate the correction value based on the reflectance sensor error. This correction was then used to adjust the motor speeds and maintain accurate tracking during turns. The PID algorithm helped smooth the robot’s movement and reduced overshooting or oscillation, especially while transitioning between different track colors. By combining sensor thresholds, timing conditions, and directional control, the robot was able to respond intelligently to track deviations and execute precise turns.

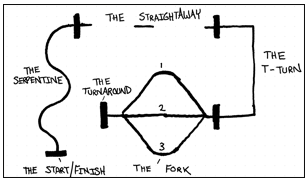

You can watch a demonstration video here UH ECE491 Competition 2024.